This project focused on transforming how Volvo Cars managed and distributed standard time documentation for service and repair jobs across global workshops. The solution replaced a manual, paper-based process with a structured, digital system designed to improve efficiency, accuracy, and scalability.

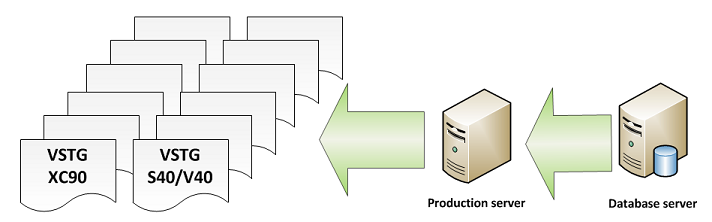

The platform enabled centralized document generation, structured data handling, and controlled distribution, supporting Volvo’s global service operations.

Overview

The solution provided comprehensive tools for managing technical documentation and delivering it in both document and application-based formats. By automating document generation and centralizing data, the system significantly reduced manual effort and operational costs.

- Automated generation of standard time documentation

- Centralized document and data management

- Structured handling of large volumes of technical content

- Multi-language support for global workshops

The project was delivered in two phases, transforming a manual, paper-based documentation process into a scalable digital solution. In the first phase, the creation of large paper binders was replaced with automated document generation, producing complete, print-ready documents directly from structured data. This enabled rapid PDF generation, eliminated manual errors, and supported the scalable production of thousands of documents using XML-based layout and styling rules.

In the second phase, the solution evolved from static documents to an application-based system, providing workshops with searchable, digital access to standard time data. The application covered all vehicle models, included advanced search functionality, and supported 16 languages, including Japanese and Chinese.

- Cost reduction of up to 95%

- Simplified production and management processes

- Elimination of paper-based distribution

- Reduced logistics and postage costs

- Environmentally friendly distribution model

- Continuous system operation and maintenance over 13 years